Alternative Collector Solutions

BACKGROUND

After many years of operating an open-pit copper-molybdenum mine in British Columbia, Canada, this mining organization announced the opening of a new standalone mineral processing plant. The flotation process used a blend of sodium isopropyl xanthate (SIPX) and diesel oil emulsion (DOE) as bulk collectors. The molybdenum facility was idled due to low market prices and high operational costs. Quadra Chemicals partnered with Chevron Phillips Chemical (referred to throughout this article as CP Chem) for lab tests and plant trials. A new collector blend was developed. SIPX and diesel oil emulsion were substituted. The molybdenum facility restarted in autumn of that year. Copper and molybdenum recoveries improved by 0.9% and 4% respectively

mining process challenge

The operator of an open-pit copper-molybdenum (Cu-Mo) mine located in British Columbia, Canada announced the opening of a new standalone mineral processing plant (commonly known as a concentrator), the acquisition of new mining equipment, and improved economic viability through a 50% decrease in strip ratio, a new National Instrument 43-101 compliant reserve, and lower comminution costs. The new target for recoveries by both concentrators were set at a rate of 86% for copper and 50% for molybdenum.

For bulk flotation process, chalcopyrite (CuFeS2) and molybdenite (MoS2) were the primary minerals to be recovered. Feed mineralogy varied as mining advanced to new ore zones. The bulk flotation circuit used a blend of sodium isopropyl xanthate (SIPX) and diesel oil emulsion (DOE) as bulk Cu-Mo collectors. pH over 10.5 was required to reach the target copper-molybdenum recovery goals. During this process, it was determined that lime consumption was high.

Unfortunately, the molybdenum recovery facility production was idled due to low market prices and high operational costs. The metallurgical group in place worked exceptionally hard to find a solution to improve recovery, hoping to restart molybdenum production as soon as possible. Testing alternative collectors became a top priority.

FIRST ROUND: COPPER RECOVERY IMPROVEMENT

A blend of dithiophosphate (DTP), thionocarbamate (TNC) and mercaptobenzothiazole (MBT) were added to the SIPX solution as secondary copper collectors, which increased copper recovery by 3%.

SECOND ROUND: MOLYBDENUM RECOVERY IMPROVEMENT

Quadra Chemicals partnered with CP Chem to participate in the second, third and fourth rounds of tests/trials.

CP Chem tested four (4) specialty collectors (represented by the red, black, blue and green curves in the diagram below) at both a low dosage and high dosage against the diesel oil emulsion (represented by the turquoise curve) at actual dosage:

Molybdenum Collector Results – Low Dosage

Molybdenum Collector Results at High Dosage

The collectors represented by the red and black curves outperformed the rest and thus were selected for plant trials. The red was trialed first during Q3 of that year due to lower cost and slightly better performance. Mo recovery increased by 8% on average; however, the operators were concerned about the odor and requested to try the other (black curve), which was odorless. Mo recovery was significantly more sensitive to grind size and feed mineralogy, resulting in a 2% increase for the first trial and 11% for the second. The odorless collector was selected by the operators to move forward as the substitute to DOE.

THIRD ROUND: OVERALL COPPER-MOLYBDENUM RECOVERY IMPROVEMENT

During Q4 of that year, after the second round of tests/trials, CP Chem tested the current blend with alternative sulfide collectors. Lab results showed copper-molybdenum recovery improvement with the addition of the new collector (green curve) to the current tested blend (blue curve):

Copper Recovery Results: New vs Legacy Solution

Molybdenum Recovery Results: New vs Legacy Solution

FOURTH ROUND: TAILINGS RECOVERY AND PH REDUCTION

Rougher tailings samples were tested to determine whether additional recovery was possible. Lab results showed that by replacing the SIPX mixture with MC17A in the secondary blend, copper-molybdenum recoveries improved by 4% and 2% respectively using the new solution.

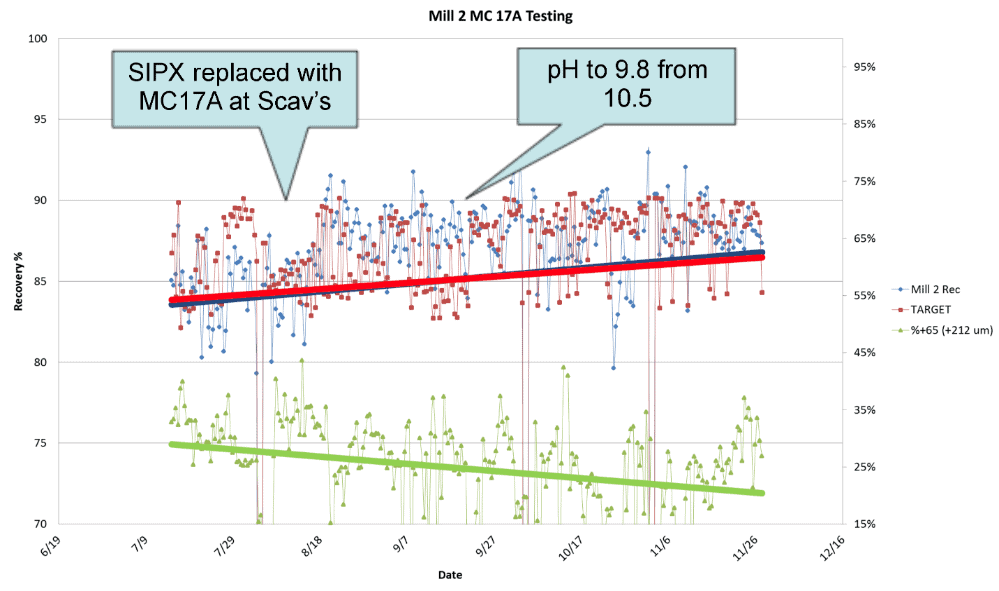

Plant trials were performed during Q3, showing copper-molybdenum recovery improvements of 0.4% and 3%. Discrepancies between lab and trial results were due to fluctuations in grind size and feed mineralogy. pH was decreased from 10.5 to 9.8 in September, with no significant recovery losses thanks to the removal of SIPX.

Tailings Recovery Comparison by Solution

Results

By the fourth quarter of that year, the specialty blend using MC17A and DTP/TNC/MTB officially replaced the SIPX/DOE mixture in production at both concentrators.

The results of the treatment are visible in these images of the tailings box from before and after the treatment using the Chevron Phillips Chemical’s application.

Tailings Box Before Custom Solution

Tailings Box Froth After Custom Solution

The scatter plot shows a noticeable copper recovery improvement at the end of July when SIPX was substituted by CP Chem’s collectors in the secondary blend, and no significant loss by mid-September when the measured pH was lowered from 10.5 to 9.8.

As expected, the new collectors were sensitive to grind size, with a 0.5% increase in copper recovery per 1% decrease in +65 mesh fraction (212 µm). Comminution presented the next opportunity for improvement.

Optimizing Copper Recovery

The new concentrator’s average grind size decreased during the third and fourth quarter of that calendar year and its effect on copper recovery was analyzed:

The scatter plot shows a noticeable copper recovery improvement at the end of July when SIPX was substituted by CP Chem’s collectors in the secondary blend, and no significant loss by mid-September when pH was lowered from 10.5 to 9.8.

As expected, the new collectors were sensitive to grind size, with a 0.5% increase in copper recovery per 1% decrease in +65 mesh fraction (212 µm). Comminution presented the next opportunity for improvement.

BENEFITS

By the fourth quarter of that year, the specialty blend using MC17A and DTP/TNC/MTB officially replaced the SIPX/DOE mixture in production at both concentrators.

The results of the treatment are visible in these images of the tailings box from before and after the treatment using the Chevron Phillips Chemical’s application.

- Improved Copper recovery by 0.9%

- Improved Molybdenum recovery by 4%

- Eliminated the use of SIPX from the recovery process, thereby reducing the carbon disulphide (CS2) vapour

- Reduced lime consumption (pH 10.5 to 9.8)